Typical Consumable Products Used by Plating Shops

Typical Consumable Products Used by Plating Shops

Blog Article

Plating facilities are integral to various industries in the United States, offering solutions that enhance the durability, appearance, and functionality of products. Behind the scenes, a range of consumable products and procedures ensures the efficiency and quality of electroplating and related operations. From chemicals to filtration systems and wastewater treatment, let's explore the key consumables crucial to plating facilities.

Plating Baths and Chemical Processes:

Central to electroplating are the plating baths, where chemical processes facilitate metal deposition. These baths require meticulous maintenance and various consumables for optimal performance. Electroplating tank heaters are essential for controlling bath temperature, vital for ensuring uniform and high-quality plating.

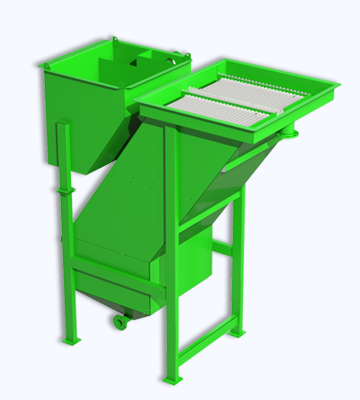

Moreover, plating bath chemicals are precisely formulated to aid metal deposition onto substrate surfaces. These formulations consist of metal salts, complexing agents, buffers, and additives tailored to specific plating needs. Looking to elevate your filtration processes? Explore the Flo King filter systems for sale. They set the standard for efficiency, reliability, and innovation in the industrial filtration realm. To improve filtration processes, consider utilizing Flo King filter systems, known for their efficiency and innovation in industrial filtration. For specialized processes like electroless nickel and anodizing, adaptable filtration systems such as Flo King Filters excel in removing contaminants while maintaining bath integrity. Their versatility allows seamless integration into different industrial processes, minimizing downtime and maximizing productivity.

Pretreatment and Plating:

Before plating, metal surfaces undergo pretreatment to ensure adhesion and corrosion resistance. This involves using formulations like degreasers, etchants, and descalers to clean and prepare surfaces, tailored to the substrate material and desired plating outcome.

During plating, electrolytic methods like chrome, silver, copper, and gold plating are common, each requiring specific consumables such as anodes, chemicals, and bath mixtures to achieve the desired coating thickness, adhesion, and appearance.

Power Sources and Temperature Control:

Precision in plating is achieved through power sources like AC to DC plating rectifiers, providing the necessary electrical current for metal deposition. These rectifiers ensure precise control over parameters like current density and voltage, critical for uniform and high-quality coatings. Equally important is temperature control, achieved through cooling systems and sensors.

Wastewater Treatment:

Effective wastewater treatment is crucial for environmental compliance and sustainability in plating operations. It addresses pollutants like heavy metals and organic compounds. Water treatment chemical suppliers specializing in water treatment offer expertise and products like coagulants, bentonite clay formulations, and flocculants to precipitate and remove contaminants. This not only safeguards the environment but also helps plating shops adhere to regulatory standards and maintain operational efficiency.

For those relying on metal plating supplies in TX, choosing the right distributor is essential. While not every distributor acts as a business processes consultant, access to a diverse range of consumable products is crucial. Each component, from plating baths to wastewater treatment solutions, plays a pivotal role in the success of plating operations. Through advanced technologies and strategic partnerships with experienced suppliers, plating facilities can innovate and thrive in a dynamic industry landscape.